SELECTION 13 580-650℃ High resistant glass colors

1. General Information and Color chart

Features!

- Intermixable and high resistant colors.

- Can mix with SELECTION 13M, metallic and interference metallic glass colors.

SELECTION 13 580-650℃ Intermixable and high resistant glass colors for bottles, cosmetic containers and glass tableware.

2. Firing Conditions

Normal firing is from 580-650℃ in a cycle of 60-150 minutes, cold-to-cold, with 10 minutes for soaking. The best firing condition depends on firing speed and type of ware and kiln.

3. Application

SELECTION 13 colors are suitable for screen-transfer printing, direct printing, spraying, pad printing and hand painting. SELECTION 13 colors contain lithium oxide. Therefore, it cannot be denied that the internal pressure resistance of the substrate decreases due to the diffusion of lithium.

4. Coefficient of Thermal Expansion (C.O.E.)

|

Product |

Thermal Expansion (C.O.E.) |

|

SELECTION 13 colors (average) |

Varies between 8.5-9.0×10-6/℃ |

|

13111 flux |

8.5×10-6/℃ |

If SELECTION 13 colors are applied in very thick layers, the colors could have pinholes or cracking, depending on the type of ware and thickness of the colors. We recommend testing the application of the colors under your conditions before mass production use.

5. Particle size of Distribution (P.S.D.)

|

Product |

D50 average |

D100 biggest |

|

SELECTION 13 colors (average) |

3.0-6.0μm (±1.0) |

30μm (±10) |

|

13111 flux |

3.5-5.5μm (±1.0) |

20μm (±10) |

6. Printing

【6.1 Mesh size】

We recommend mesh sizes that are 195-305 mesh/inch (77-120 thread/cm) for all screen applications.

【6.2 Medium ratio】

|

Product |

Color : medium |

Recommended mesh |

|

SELECTION 13 colors: Medium PM2/PMT8 |

10 : 5-7/6-8 |

195-305 mesh/inch (77-120 thread/cm) |

|

13111 flux: Medium PM2 |

10 : 5.5-8 |

195-305 mesh/inch (77-120 thread/cm) |

Screen-transfer printing: We recommend PM2 flowing medium, PMT8 thixotropic medium for dot and four-color printing. We recommend C12 cover coat by printing 70 mesh/inch (27 thread/cm).

To avoid glass colors absorb any moisture easily. Therefore, keep powder colors in a dry place. We recommend drying the color powder before using.

7. Color and Mixability

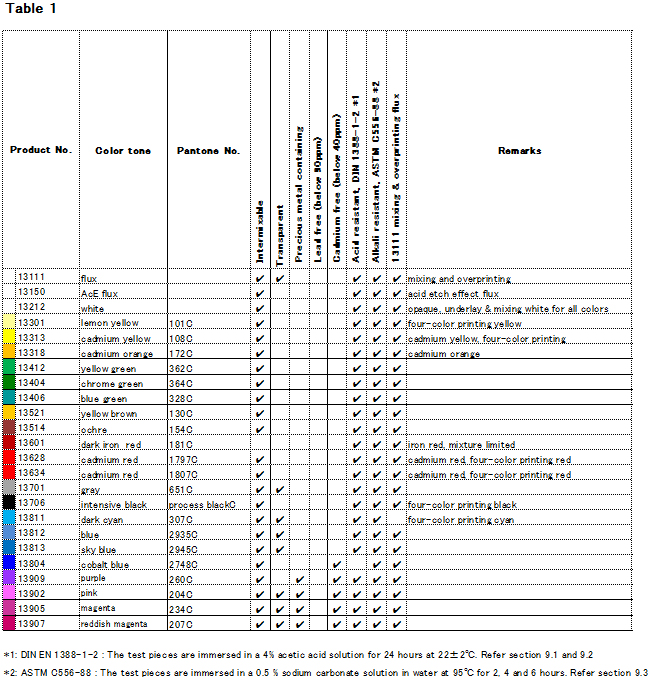

SELECTION 13 colors can be mixed with each other in any proportions. However, we recommend testing the stability of mixing colors and overprinted flux colors under end-user’s firing conditions before mass production. Please note following points and refer to Table 1.

Underlay white: 13212 white is suitable as underlay white for all colors.

Mixing white: To obtain pastel-color tone, it is suitable to mix 13212 white.

Mixing flux: 13111 flux is suitable for mixing all colors. After mixing with flux, the color is lighter and glossier.

Overprinting flux: Overprinting 13111 flux can improve color gloss and chemical durability, such as heavy metal release, alkali durability and dishwasher resistance.

AcE flux: To obtain acid etch effect, 13150 AcE flux is suitable.

Iron red: 13601 iron red is not recommended for mixing with cadmium-containing colors.

Black: 13706 black is very intensive and it is recommended for four color printing and underlay black for metallic colors.

Cadmium-containing colors *1: 13313 yellow, 13318 orange, 13628 red and 13634 red can be mixed with any other SELECTION 13 colors except 13601 iron red.

Precious metal containing colors : 13909 purple, 13902 pink, 13905 magenta and 13907 red magenta contain gold and they can be mixed with any other SELECTION 13 colors. 13902 pink and 13907 red magenta cannot mix with above cadmium-containing colors *1

8. Four-color printing

【8.1 Choice of colors】

|

|

Combination 1 (without cadmium colors) |

Combination 2 (with cadmium colors) |

|

Yellow |

13301 yellow |

13313 cadmium yellow |

|

Magenta |

13905 magenta, 13907 red magenta |

13905 magenta |

|

Red |

|

13628 cadmium red |

|

Cyan |

138 11 cyan |

13811 cyan |

|

Black |

13706 black |

13706 black |

|

Flux |

13111 mixing and overprinting flux |

13111 mixing and overprinting flux |

13301 yellow and 13313 cadmium yellow cannot be mixed with each other and overprinted.

13628 cadmium red and 13905 magenta can be mixed each other and overprinted.

13111 flux are suitable as overprinting flux for all colors.

【8.2 Printing order】

Combination 1, Y-M-C-K-F: yellow → magenta → cyan → black → overprinting flux.

Combination 2, CdY-M/CdR-C-K-F: cadmium yellow → magenta/cadmium red → cyan → black → overprinting flux. (Additional overprinting of cadmium colors is possible before overprinting 13111 flux).

【8.3 Mesh size】

We recommend mesh sizes that are 250-305 mesh/inch (100-120 thread/cm) for all screen applications.

【8.4 Medium ratio】

|

13301 yellow , 13313 c admium yellow : PMT8 |

10 : 5-7 |

|

13905 magenta, 13907 red magenta : PMT8 |

10 : 5-7 |

|

13628 cadmium red : PMT8 |

10 : 5-7 |

|

13811 cyan : PMT8 |

10 : 5-7 |

|

13706 black : PMT8 |

10 : 5-7 |

|

13111 overprinting flux : PM2 |

10 : 5.5-8 |

We recommend PMT8 thixotropic medium for printing SELECTION 13 four-colors.

We recommend PM2 flowing medium for overprinting 13111 flux.

We recommend C12 cover coat by printing 70 mesh/inch (27 thread/cm)

9. Chemical durability (refer to the Table 1)

Chemical durability of SELECTION 13 colors depends on type of ware, kiln, color deposit and firing conditions. The following are the results of tests on soda lime glass bottle, fired at 600℃, with 10 minutes of soaking time and 90 minutes of cold-to-cold firing conditions of gas kiln in production.

【9.1 Lead and cadmium release】

According to the DI EN 1388-1-2 test, SELECTION 13 colors show less than lead 0.8 mg/dm2 and cadmium 0.07 mg/dm2 releases.

【9.2 Acid resistance】

According to the DI EN 1388-1-2 test, SELECTION 13 colors do not show any visible attack after immersion in a 4% acetic acid solution for 24 hours at a room temperature of 22±2℃, except 13804 cobalt blue.

【9.3 Alkali resistance】

According to the ASTM C556-88 test, SELECTION 13 colors do not show any visible attack for up to 4 hours.

Overprinting 13111 flux can improve color gloss and chemical durability, such as lead and cadmium release, acid and alkali durability and dishwasher resistance.

10. Safety Data Sheet (SDS)

Safety data sheet (SDS) of SELECTION 13 colors are available on request.

The above information and statements are unsolicited. IZAWA PIGMENT CO., LTD. provides them to promote its products. The above information and statements are also believed to be accurate at the time of publication under their laboratory conditions. Use of them is at the sole discretion of the user and IZAWA PIGMENT CO., LTD. does not give any warranty with respect to any test results. In no event shall IZAWA PIGMENT CO., LTD. be liable for any direct, indirect, special, incidental, or consequential damages arising out of the use of the above information.

Click to download:  TI-SELECTION 13 5-7-2024.doc TI-SELECTION 13 5-7-2024.doc  TI-SELECTION 13 5-7-2024 .pdf TI-SELECTION 13 5-7-2024 .pdf |